10 Best Automotive Wire Connectors 2025 in the United States

Winner

Nilight - 50004R 120 Pcs/60 Pairs Quick Splice Wire Terminals T-Tap Self-stripping with Nylon Fully Insulated Male Quick Disconnects Kit, 2 Years Warranty

The Nilight - 50004R is a versatile set of automotive wire connectors, including 60 pairs of T-tap connectors and male quick disconnects, making it suitable for various wiring projects, such as in marine, automotive, scientific, and home applications. The connectors are designed to be self-stripping, simplifying the process of tapping into existing wires and saving time and effort for users.

Most important from

28161 reviews

Haisstronica Crimping Tool for Non-Insulated Open Barrel Terminals Receptacles,AWG 20-10 Ratchet Wire Crimper Tool,Wire Terminal Crimper HS-5327

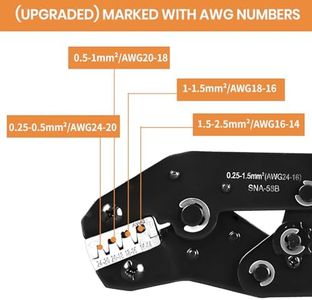

The Haisstronica Crimping Tool for Non-Insulated Open Barrel Terminals (HS-5327) is designed for professionals and hobbyists looking for a reliable wire crimper. It supports a range of wire gauges (AWG 20-10), making it versatile for various automotive wiring tasks. The tool features a precise ratchet structure that automatically adjusts for different wire sizes, ensuring secure crimps without damaging the terminal shell. An adjustable crimp force further tailors the tool to your specific needs, enhancing its usability across different applications.

Most important from

6719 reviews

Nilight - 50020R 2Pin Way 16AWG Waterproof Wire 1.5mm Series Terminal Connector-10 Pack,2 Years Warranty

The Nilight 50020R is a pack of 10 waterproof wire connectors that are designed for a range of applications including marine, automotive, and motorcycle use. These connectors are 2-pin, quick-connect types, which makes them suitable for easy and fast installations. The connectors use 16 AWG wire, making them versatile for most standard wiring needs.

Most important from

7544 reviews

Top 10 Best Automotive Wire Connectors 2025 in the United States

Winner

9.9 score

Nilight - 50004R 120 Pcs/60 Pairs Quick Splice Wire Terminals T-Tap Self-stripping with Nylon Fully Insulated Male Quick Disconnects Kit, 2 Years Warranty

Nilight - 50004R 120 Pcs/60 Pairs Quick Splice Wire Terminals T-Tap Self-stripping with Nylon Fully Insulated Male Quick Disconnects Kit, 2 Years Warranty

Chosen by 1378 this week

Haisstronica Crimping Tool for Non-Insulated Open Barrel Terminals Receptacles,AWG 20-10 Ratchet Wire Crimper Tool,Wire Terminal Crimper HS-5327

Haisstronica Crimping Tool for Non-Insulated Open Barrel Terminals Receptacles,AWG 20-10 Ratchet Wire Crimper Tool,Wire Terminal Crimper HS-5327

Nilight - 50020R 2Pin Way 16AWG Waterproof Wire 1.5mm Series Terminal Connector-10 Pack,2 Years Warranty

Nilight - 50020R 2Pin Way 16AWG Waterproof Wire 1.5mm Series Terminal Connector-10 Pack,2 Years Warranty

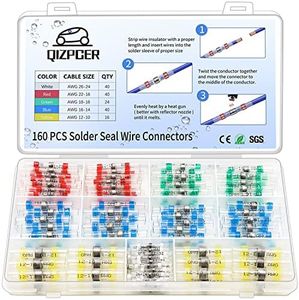

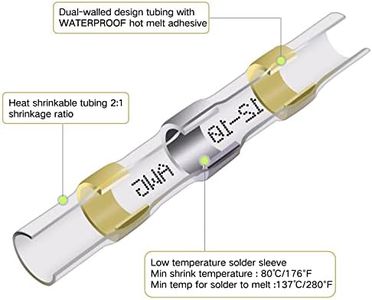

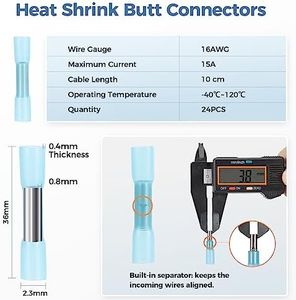

160 Pcs Solder Seal Wire Connectors Kit, Electrical Connectors Heat Shrink Wire Connectors Waterproof Electrical Cable Butt Terminals for Marine Automotive Trailer RV Boat Truck Wiring

160 Pcs Solder Seal Wire Connectors Kit, Electrical Connectors Heat Shrink Wire Connectors Waterproof Electrical Cable Butt Terminals for Marine Automotive Trailer RV Boat Truck Wiring

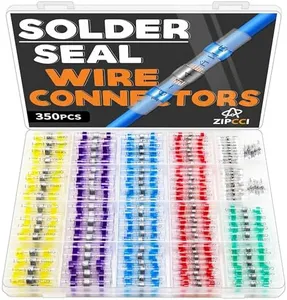

ZIPCCI 350Pcs Wire Connectors Kit - Solder Seal Wire Connectors, Heat Shrink Butt Connectors, Waterproof - Electrical Terminal Splice, Marine Grade - Gauge Wiring, Crimp - Trailer, Automotive, DIY

ZIPCCI 350Pcs Wire Connectors Kit - Solder Seal Wire Connectors, Heat Shrink Butt Connectors, Waterproof - Electrical Terminal Splice, Marine Grade - Gauge Wiring, Crimp - Trailer, Automotive, DIY

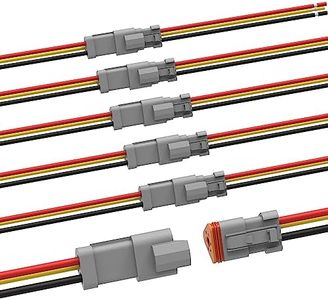

482 PCS DT Deustch Connector Kit, 2 3 4 6 8 12 Pin Waterproof Automotive Electrical Connectors, Including Deutsch Crimping Tool, Removal Tool, 16# Solid Contacts

482 PCS DT Deustch Connector Kit, 2 3 4 6 8 12 Pin Waterproof Automotive Electrical Connectors, Including Deutsch Crimping Tool, Removal Tool, 16# Solid Contacts

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.